AUS ANTS YTONG NESTS

We have been successfully keeping ants for many years. Now, we are proud to offer the very pinnacle in ant keeping technology. Our Ytong nests are of the highest quality and will easily satisfy the needs of amateur, and professional ant keepers alike.

OUR CURRENT RANGE

Founding

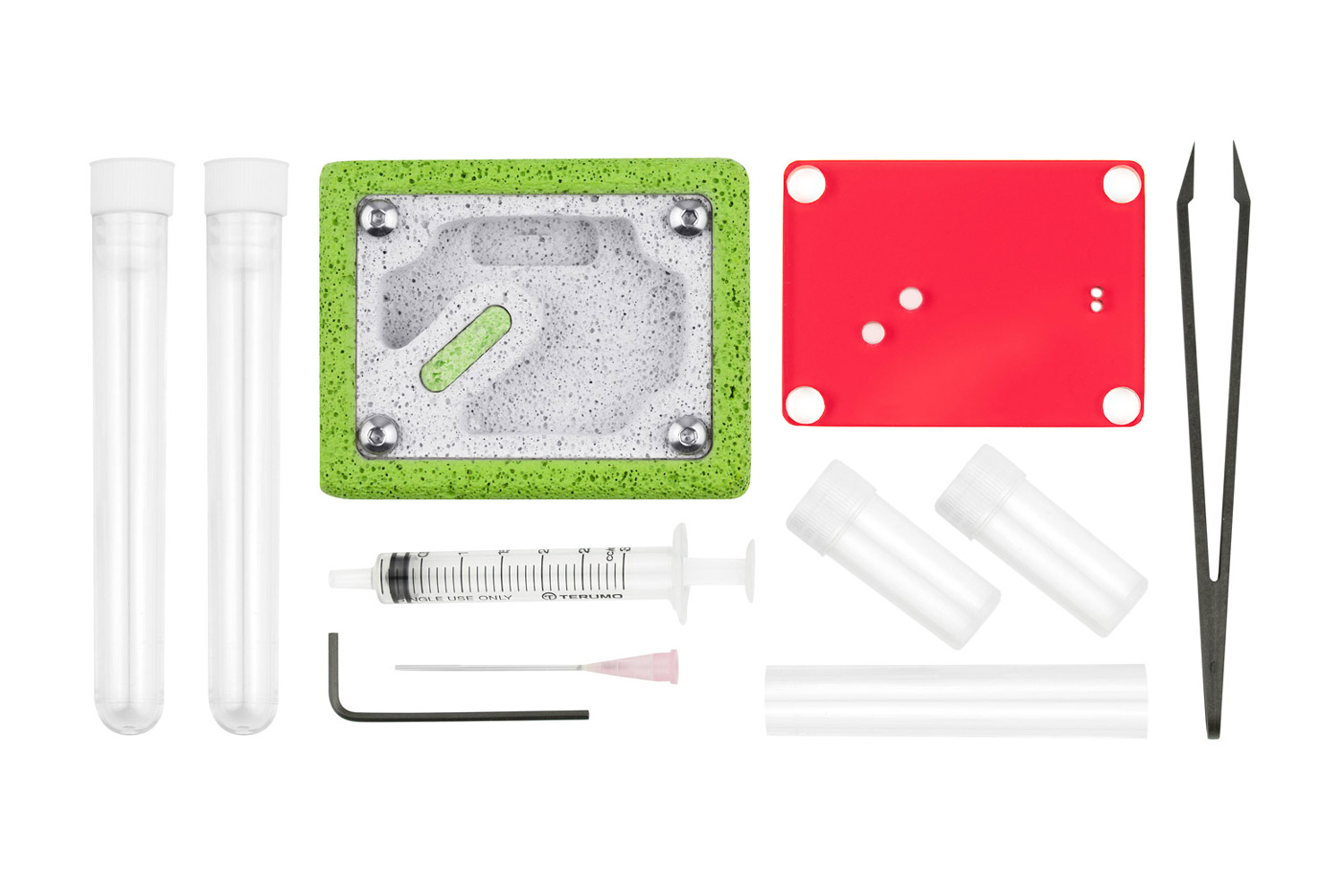

Available in our Ytong Starter Kit

Suitable for 1 to 500 ants

Length - 84 mm

Width - 65 mm

Overall Depth - 38 mm

Chamber Depth - 10 mm

Small

Available individually

Suitable for 50 to 1,000 ants

Length - 120 mm

Width - 95 mm

Overall Depth - 38 mm

Chamber Depth - 10 mm

Medium

Available individually

Suitable for 100 to 2,000 ants

Length - 175 mm

Width - 135 mm

Overall Depth - 38 mm

Chamber Depth - 10 mm

Large

Available individually

Suitable for 200 to 5,000 ants

Length - 245 mm

Width - 195 mm

Overall Depth - 38 mm

Chamber Depth - 10 mm

WHY PICK oUR YTONG NESTS?

Here at Aus Ants, we have been keeping ants for many years. One look at our YouTube channel ‘Ants Australia’ and it's clear, we know what we’re talking about. To develop our Ytong nests we poured all of our knowledge and ant keeping experience into designing, producing, and then meticulously testing hundreds of nests, until eventually, we arrived at our current designs. Each aspect has been carefully considered and developed with both the occupants and caretakers in mind. We strongly believe that our Ytong nests are the best formicaria on the market!

How can we make such bold claims? Well, after extensive testing we became a real fan of Ytong and its beneficial properties, but this material alone was not enough to guarantee the success of our colonies. We quickly realised that the design of the nests and how it is manufactured is of the utmost importance. Therefore, we work very hard to ensure the end result is nothing short of perfection.

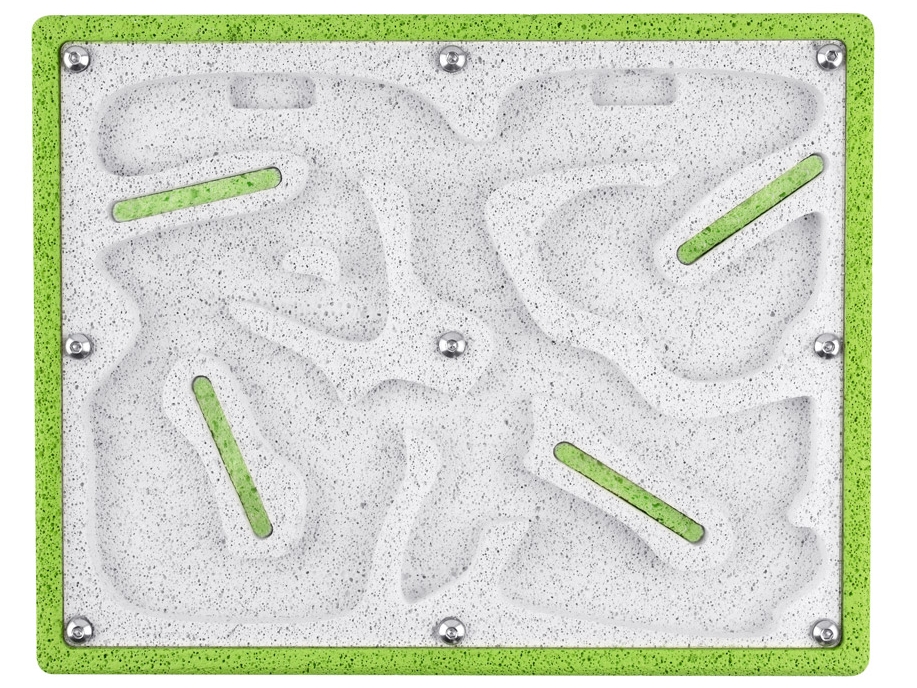

Some of our favourite features of our Ytong nests include...The Ytong itself! From the moisture retentive properties that lead to stable humidity levels...to its excellent insulative properties, helping to keep temperature fluctuations to a minimum (much like wild ants living underground would be accustomed to)...to the material's porous surface, making it easy for any type of ant to grip onto, as well as aiding the developing larvae in the spinning of their protective silken cocoons. Ytong really is perfect for the job!

The removable, crystal-clear acrylic lids are secured in place by stainless steel bolts which are screwed into a machined metal thread embedded into the Ytong. This not only provides a clearer view of the ants but also allows easy removal of the lid for cleaning purposes. The lids also feature laser cut micro holes for improved ventilation.

The entrance/exit holes are designed to holster standard 10mm internal (13mm external) vinyl tubing, which is the same as the minimum chamber depth of the nest. This allows the ants to travel in and out of the nest unhindered by a reduction of tube diameter surrounding the connection point (which often results in bottle-necking of the ants' traffic). This also allows larger species to comfortably enter/exit the nest.

SO WHAT IS YTONG?

The primary ingredient; Ytong is a versatile, high performance and durable material. It is often branded as 'Hebel' in Australia and is made from autoclaved aerated concrete (AAC for short). AAC replicates minerals found in nature. It is made of raw materials such as sand, cement, lime and gypsum, which is then combined with water and an expansion agent. The mixture then expands with the help of a gas, giving the material its highly porous qualities. This creates a sturdy, yet extremely light material. Perfect for the nurturing of an ant colony.

AAC is...

Non toxic

Highly sustainable

Produced locally in Australia

Naturally mold resistant

A fantastic thermal insulator

Moisture retentive with high dispersion qualities

HOW WE DO IT - All our secrets!

Ytong has been used for many years in ant keeping, but it has always had its drawbacks. Such as, its comparatively poor water retentive qualities (in its raw form), resulting in the need to constantly hydrate; the necessity of bulky and heavy formats in order to maintain strength, and once carved, it's almost impossible to post affordably. We have overcome all these problems and added significant improvements to the use of this material.

We take the Ytong in its bare block form and machine them down to 30mm slabs. To these slabs we then laminate a quality compressed timber fiber board using the world's strongest and safest marine-grade epoxy.

This epoxy soaks into the base layers of the Ytong, performing 2 main roles;

1. It significantly strengthens the blocks of Ytong, making it far more durable and possible to machine further. This also makes the final product much lighter and compact.

2. It seals the entire base and waterproofs the Ytong. This is important to prevent ingress of liquids from external sources and it effectively seals the ytong, thus, reducing evaporation rates.

Once prepared into composite slabs, we then head on over to the CNC machines. The CNC machines are calibrated to carve out the nest interior, hydration spaces and rebates for the lid. Rebating the lid is important to help seal up the nest from escapees and makes a safer product to handle, no sharp edges.

With the larger nest sizes comes the option to have multiple hydration spaces. This allows the caretaker to alternate between them, thus, greatly reducing the chance of mold and bacteria growth. We recommend hydrating only one side at a time to give the ants a humidity gradient. The Ytong that we use is mold resistant and the sponge is also antibacterial to help keep the nest healthy.

Once fully machined, using our state of the art equipment, the Ytong formicaria are then individually hand finished and checked for defects. Although, this does consume a fair bit of time per unit, we believe it is important to give each nest a practical and durable finish.

After the final hand finishing, the sealing, and painting happens. The nests receive 2 coats of a durable non toxic paint finish with two rounds of hand sanding. This specialised paint coating is done in such a way that around 95% of the Ytong is sealed, this enables the nests to breath naturally. After extensive testing and practical use of the nests, we have arrived at the optimum evaporation and ventilation rates to simulate natural nesting environments.

Final assembly can begin after the protective paint layer has had a couple of days to fully cure. The biodegradable hydration media is installed and lids fitted. The lids are made of a high clarity 3 mm cast acrylic (Not glass, much safer for children and transport) with holes cut in both for hydration and the stainless steel bolts to fix the lid in place. The lids do not need to be glued, this means that once the colony moves out, the lids can easily be unscrewed, and the nest can be cleaned and reused.

We use a 10mm internal diameter vinyl tube to connect the nests up to additional ones or outworlds (foraging arenas). This tube can easily be scaled up or down with a vinyl tube joiner based on your ants' requirements.

ANT SHIELDS

Made of high clarity, crystal clear acrylic, these shields are specifically designed to be placed upon a corresponding sized nest within our range of Ytong and Acrylic designs.

What are they for? Well, many species of ants, (and other insects too) are unable to sense wavelengths within the red light spectrum. So, when the shields are fitted, the ants are fooled into thinking they’re safe within the security of darkness (as ant colonies would naturally be in the wild). Like a one way mirror, the keeper can see in, but the ants can’t see out. Thus, allowing for a more natural, disturbance free view of all the exciting happenings within the nest. Just keep in mind, the effectiveness of the shields may vary from species to species, and works best under low light intensities.

Plus, as the shields completely cover the lids of their corresponding nests, they also help protect the lids beneath from dust accumulation and scratching. The shields are designed to comfortably rest on top of the nests’ screws, leaving a very thin, but important, gap between them and the clear acrylic lid below. Thus, preventing the two rubbing together and forming unsightly marks and scratches.

Additional holes have been carefully cut into the shields. Some for hydration, allowing the keeper to inject water directly into the nests’ hydration chambers without having to remove the shields, and other, smaller holes are present for ventilation purposes.

Our ‘Ant Shields’ come included in our ‘Acrylic/Ytong Starter Kits’ and are sold separately for our ‘Small’, ‘Medium’ and ‘Large’ sized nests.

YTONG oR ACRYLIC NEST? HOW TO DECIDE?

Both our acrylic and ytong nests are perfectly suitable for raising virtually all ant species, so it mostly boils down to personal preference. We feel however, that ytong is the superior, but not in all cases...

YTONG

The main advantages of ytong (used in our nests) is that it is extremely water retentive, so you won't have to hydrate the nest as often as the acrylic designs. They also offer a slightly larger chamber depth (10mm) when compared with our acrylic nests (9mm). Making them more suitable for larger ants, such as Bull Ants (Myrmecia spp.). The material also possesses greater insulative properties. Which is ideal for keeping temperature and humidity levels stable (replicating the conditions wild ants would experience when living below the ground surface).

Another advantage of the material is the surface texture. The rough, porous surface allows the ants to easily grip on, offering them maximum maneuverability (especially useful for ant species which have trouble gripping onto smooth surfaces, such as plastic and glass). Plus, this improved grip can also aid the ant larvae in the spinning of their cocoons.

With a little DIY work, (using a screwdriver or a drill) the inner chambers can easily be carved. Giving you the option of increasing chamber depth to accommodate for larger ant species or colonies, or to better match your unique aesthetic needs! We demonstrate how best to carve ytong in Part 2 of our ‘How to Build an Ant Nest’ video series here.

ACRYLIC

One advantage of acrylic is that it is assembled extremely securely. Making it a great choice for tiny ant species which may be able to squeeze through the lids of our porous Ytong designs (such as Monomorium spp.). Plus, the robust nature of acrylic allows it to be infinitely reused. Simply move your colony out, disassemble the nest, give it a good clean under some hot water, then reassemble, and it’s ready to house ants once again!

HOW TO USE?

HYDRATION

Our ytong nests requires around 5-10 ml of water every 4 to 7 days, depending upon ambient temperature and the particular ant species being housed (as some ants may prefer their nest wetter or drier than others). We advise doing some research and experimenting in order to determine your ant species’ ideal humidity preferences.

To reduce the risk of ‘over-hydration’ of the nest, moisten the sponge slowly so that the water can be properly absorbed. Ytong is a highly porous material so shortly after hydration, the sponge may appear to be dry, however, this not a sign that the nest is in need of more moisture, the water has simply transferred into the Ytong itself. It is the Ytong which regulates the humidity of the nest by slowly releasing this moisture evenly over time, not the sponges.

LEARN MORE

To learn more about our range of Ytong formicaria and how best to use them, we highly recommend watching this informative introductory video below.